Air Tightness FAQ

What is Building Air-Tightness?

Building airtightness (also called envelope airtightness) can be defined as the resistance to inward or outward air leakage through unintentional leakage points or areas in the building envelope. This air leakage is driven by differential pressures across the building envelope due to the combined effects of stack, external wind and mechanical ventilation systems [1].

[1] G. Guyot, F. R. Carrié and P. Schild, “Project ASIEPI – Stimulation of good building and ductwork airtightness through EPBD,” 2010.

What is infiltration / exfiltration?

Infiltration/exfiltration is the uncontrolled inward/outward leakage of outdoor/indoor air through cracks, interstices and other unintentional openings of a building, caused by the pressure effects of the wind and/or the stack effect [1].

[1] M. Limb, “Technical note AIVC 36- Air Infiltration and Ventilation Glossary,” International Energy Agency energy conservation in buildings and community systems programme, 1992.

What is the energy impact of building & ductwork airtightness?

The implementation of the EPBD recast puts increasing pressure to achieve better building and ductwork airtightness since for most European climates and countries, good airtightness levels are necessary to achieve nearly zero-energy buildings. This has been shown in a number of studies with energy impacts of the order of 10 kWh per m2 of floor area per year for the heating needs in a moderately cold region (2 500 degree-days) and 0 to 5 kWh/m2/year for the ducts plus the additional fan energy use [1].

For more information see also the ASIEPI project technical report on building and ductwork airtightness as well as REHVA journals’ special issue on airtightness [2].

[1]G. Guyot, F. R. Carrié and P. Schild, “Project ASIEPI – Stimulation of good building and ductwork airtightness through EPBD,” 2010.

[2] R. Coxon, “Research into the effect of improving airtightness in a typical UK dwelling,” The REHVA European HVAC Journal-Special issue on airtightness, vol. 50, no. 1, pp. 24-27, 2013.

Is good building airtightness compatible with good indoor air quality?

Under the Irish Building Regulations Part (F) you are required to have adequate ventilation for healthy living.

Therefore yes, provided that the building is equipped with an appropriate well-designed ventilation strategy/system (whether natural, mechanical or hybrid).

Better building airtightness converges with better indoor air quality because the ventilation system operates more efficiently. Building leaks cause uncontrolled airflows and potentially poorly ventilated rooms although the total building air exchange rate may be sufficient.

How is airtightness quantified?

The airtightness of a building is often expressed in terms of the leakage airflow rate through the building’s envelope at a given reference pressure (usually 50 Pa) divided by the:

– heated building volume V. At 50 Pa, it is called the air change rate at 50 Pa and noted n50.

– envelope area AE. At 50 Pa, it is called the air permeability at 50 Pa and noted q50.

The n50 is the air change rate at and is expressed in air changes per hour (ac/h). It is the relationship between the total volume of air in m³ and how often leaks in the building envelope allow the air to exchange at 50 Pascals air pressure difference. The q50 is the air permeability rate and is expressed as m³ h m². It is an expression of the amount of air leaked from the dwelling in relation to the total exposed surface area of the building (i.e. the ground floor, all exposed ceilings and all external walls[including party walls/floors in the case of semi-detached, terraced or apartment dwellings) at 50 Pascals pressure. The maximum upper limit allowed according to the 2011 Irish Building Regulations Technical Guidance Documents Part (L) is 7 m³ h m².

What are the most common air leakage/infiltration paths?

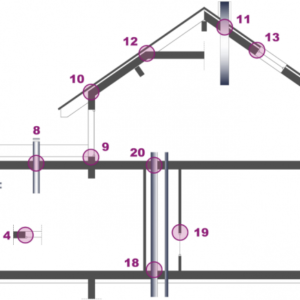

Common leakage sites are listed in Figure 1 below. Figure 2 gives the classification of these sites in 4 categories [1]:

Common leakage sites are listed in Figure 1 below. Figure 2 gives the classification of these sites in 4 categories [1]:

1. Junction lower floor / vertical wall

2. Junction window sill / vertical wall

3. Junction window lintel / vertical wall

4. Junction window reveal / vertical wall (horizontal view)

5. Vertical wall (Cross section)

6. Perforation vertical wall

7. Junction top floor / vertical wall

8. Penetration of top floor

9. Junction French window / vertical wall

10. Junction inclined roof / vertical wall

11. Penetration inclined roof

12. Junction inclined roof / roof ridge

13 . Junction inclined roof / window

14. Junction rolling blind / vertical wall

15. Junction intermediate floor / vertical wall

16. Junction exterior door lintel / vertical wall

17. Junction exterior door sill / sill

18. Penetration lower floor / crawlspace or basement

19. Junction service shaft / access door

20. Junction internal wall / intermediate floor

[1]F. Carrié, R. Jobert and V. Leprince, “Contributed Report 14- Methods and techniques for airtight buildings,” AIVC, 2012.

What is an air tightness barrier?

Air barriers control the unintended movement of air into and out of a building enclosure and form the last barrier between the inside heating building and the external atmosphere.

It can be a combination of materials including plasters membranes, tapes, mastics etc. designed and manufacture for building life long functionality.

What is a blower door or blower door test?

Commonly called a blower door it is a device (fan and associated control mechanisms and software) that fits into a doorway or building, containing a fan, for supplying or extracting a measured rate of air flow. It is normally used for testing air leakage by pressurisation or depressurisation.

The result can be used to identify the building performance against Building Regulations, design specification or target for the BER/Passive House NZEB standards.

What is airtightness/air leakage testing? What is fan pressurisation?

It is a method of quantifying how much air leaks into or out of an enclosure according to the European Standard IS EN 13829. EN 13829 gives a standard test method for buildings.

Building airtightness levels can be measured by using a fan, temporarily installed in the building envelope (a blower door) to pressurise the building. Air flow through the fan creates an internal, uniform, static pressure within the building.

The aim of this type of measurement is to relate the pressure differential across the envelope to the air flow rate required to produce it.

Generally, the higher the flow rate required to produce a given pressure difference, the less airtight (leaky) the building.

What are the impacts of poor envelope airtightness on ventilation, indoor air quality and building damage?

Because air infiltration is uncontrolled, poor envelope airtightness may affect:

Indoor air quality: Some rooms may be largely under-ventilated (i.e. stuffy, high CO2 levels etc. ) while other are over-ventilated (draughty, cold etc.).

Energy use: Air leakage may inadequately increase the total ventilation airflow rate; or it may not allow sufficient heat recovery (in case of a systems with heat recovery devices, the unit will only recover heat on the airflow passing through it).

Building materials: Air leaking out of the envelope may cause condensation damage as its temperature drops below dew point.

Definition of terms used for tightening products –

Adhesive: Substance that holds one surface to another surface by attachment.

Adhesive membrane: Flexible film (generally made of polyethylene) associated with a no woven fabric used to seal joints between the peripheral of a window and a vapour barrier/retarder or a plaster.

Bond: Material used to tie or fasten things together.

Expanding foam: Expanding material (generally polyurethane-based) applied to fill gaps, to fix doors and to insulate connecting joints (especially between window frames and wall). Not considered long life airtight as the material can breakdown over time.

Fastener: Material used to bind things securely together.

Grommet: Material used to create an airtight seal around circular-section elements such as plumbing pipes, electrical conduits or cables as these pass through the airtight layer.

Joint: Location where several parts of the structure (building or ductwork) meet.

Sealant: A material that has the properties to join 2 surfaces together to prevent gases, liquids or solids from passing between these surfaces.

Mastic: Putty-like sealant.

Plasters: Fluid or paste-like mixtures made of cement, lime, or gypsum. These products are spread or projected on the surface.

Pre-compressed tapes: (also called pre-compressed foams) Rolls a few centimetres wide whose thickness is reduced when rolled-up and slowly get thicker when installed. They are made of polyurethane or polyester foams impregnated with a synthetic butyl or acrylic resin. The retarded decompression process allows the gaps to be filled while the foam was put without force into them.

Repair tape: Oversized tape roll or flat patch typically used to repair holes in films or holes made on purpose e.g., for blowing insulation.

Tape: An adhesive in the physical form of a tape, i.e., a narrow strip of material.

Vapour barriers or retarders: Membranes or films of large areas originally intended to limit or regulate vapour transfer within vertical walls and roofs. When properly installed and at the right location, they prevent interstitial condensation, in particular in the insulation layer. Their composition can be very diverse, e.g. they can be partly made of polyethylene, polyester, polyane, aluminium, etc. They are usually airtight unless perforated.